Using the Hot Knife

The Hot Knife Tool has special artwork requirements.

Creating artwork for the Hot Knife tool

The Hot Knife is designed to be able to cut Styrofoam up to 32mm thick. Tooli has 10mm Z stroke so has to enter the foam sheet from the side. Tooli cannot plunge into the foam with the Hot Knife.

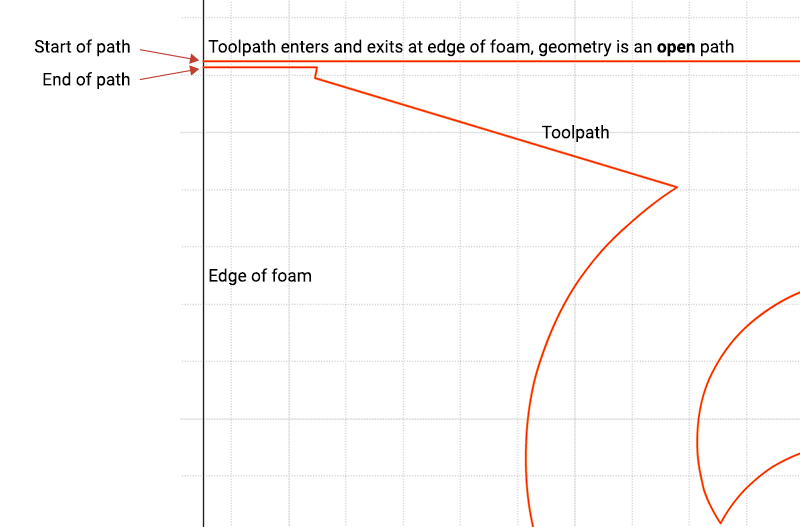

To allow for this... when producing artwork for the Hot Knife, geometry needs to be added to the artwork to create a path to and from the edge of the foam sheet. Your artwork must only contain open shapes so that Art2Gcode can easily find the correct start and end points. Each end of a path must touch the same edge of the foam sheet.

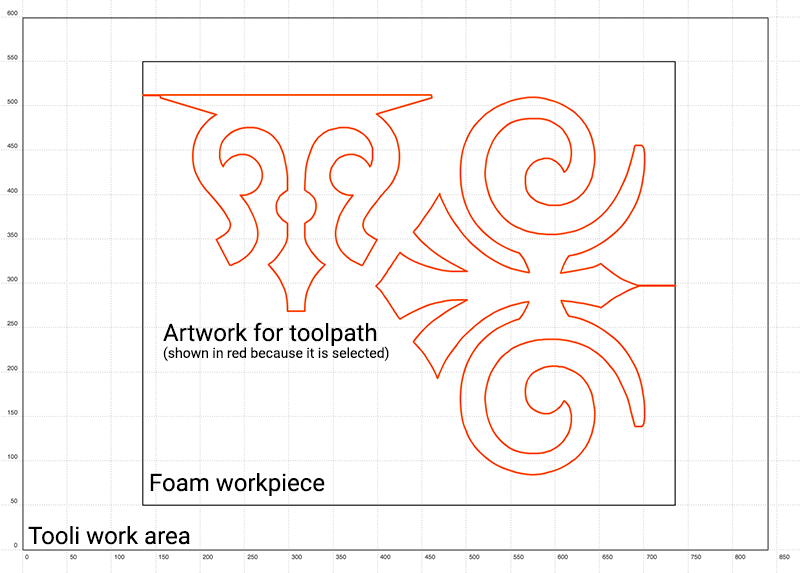

Pictured above are two shapes with the correct modifications - they were produced in illustrator. Both shapes are open, and lead-in from and out-to the edge of the foam sheet. Art2Gcode will direct Tooli to only move around the perimeter of the sheet (offset 10mm), when moving to and from each shape.

Shown below is a closer view of the entry and exit point of the artwork.

Important!

Before running a Hot Knife job on Tooli, the Hot Knife must be positioned behind the back edge of the foam sheet at job start.

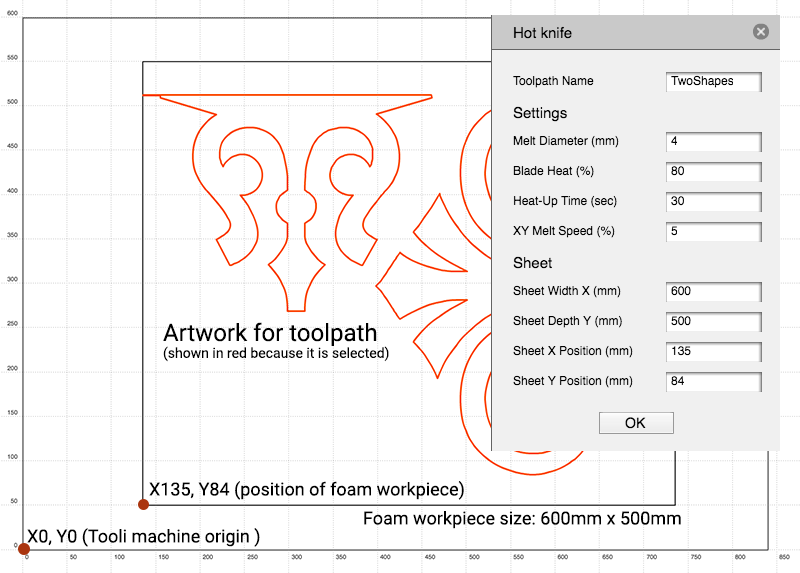

Creating a Hot Knife toolpath

Select the desired geometry to be processed and in the menu click 'CAM' and select 'Hot Knife'.

The Hot Knife toolpath setting dialogue box will appear. Settings are explained below.

- Toolpath Name - Give your toolpath a name, this is useful to help identify different toolpaths within the file and when exporting.

- Melt Diameter (mm) - The expected width of the melt gap created by the blade. By default it is set to 4mm, but may vary depending on the material you are cutting, the heat setting and the speed of the travel. Although this setting is not actually used to create a Hot Knife Gcode file, it can be useful for visualising the end result.

- Blade Heat (%) - Set the heat here, the unit of measure is a percentage of the tools maximum heat setting.

- Heat-Up Time (sec) - A period of time (in seconds) at the beginning of the job where Tooli will wait for the Hot Knife to come upto temperature, before proceeding. Obviously if the blade tried to enter the foam while it was still cold, the outcome would be undesirable. The default setting of 30 seconds should be enough time in most instances.

- XY Melt Speed (%) - Set the speed the toolhead travels while melting through the foam. The unit of measure is a percentage of Toolis maximum feed speed. It is reccommended to be conservative with this setting, as moving faster than the blade can melt may result in a bent or broken blade. The default setting of 5% is a good starting point in most instances.

- Sheet width (mm) - The width of your foam workpiece. Measured across the X-axis of the machine.

- Sheet Depth (mm) - The depth (not thickness) of your foam workpiece. Measured along the Y-axis of the machine (front to back).

- Sheet X position (mm) - The X position of the left edge of your foam sheet. Minimum 10mm required.

- Sheet Y position (mm) - The Y position of the front edge of your foam sheet. Minimum 10mm required.

Settings

Sheet

These settings inform Tooli of the size and position of the foam sheet - so Tooli can move around it when travelling between shapes. The maximum sheet size is 20mm less than your Tooli's process size, in both directions. This allows 10mm clearance around the perimeter for the blade to travel to and from shapes.